This blog post has been researched, edited, and approved by John Hanning and Brian Wages. Join our newsletter below.

Why Manufacturers Are Leaving Money on the Table

Manufacturing is a nonstop balancing act—higher materials costs, labor shortages, supply chain unpredictability, and the constant pressure to modernize. Yet in the middle of all this, many manufacturers overlook valuable tax incentives built specifically to ease these financial burdens.

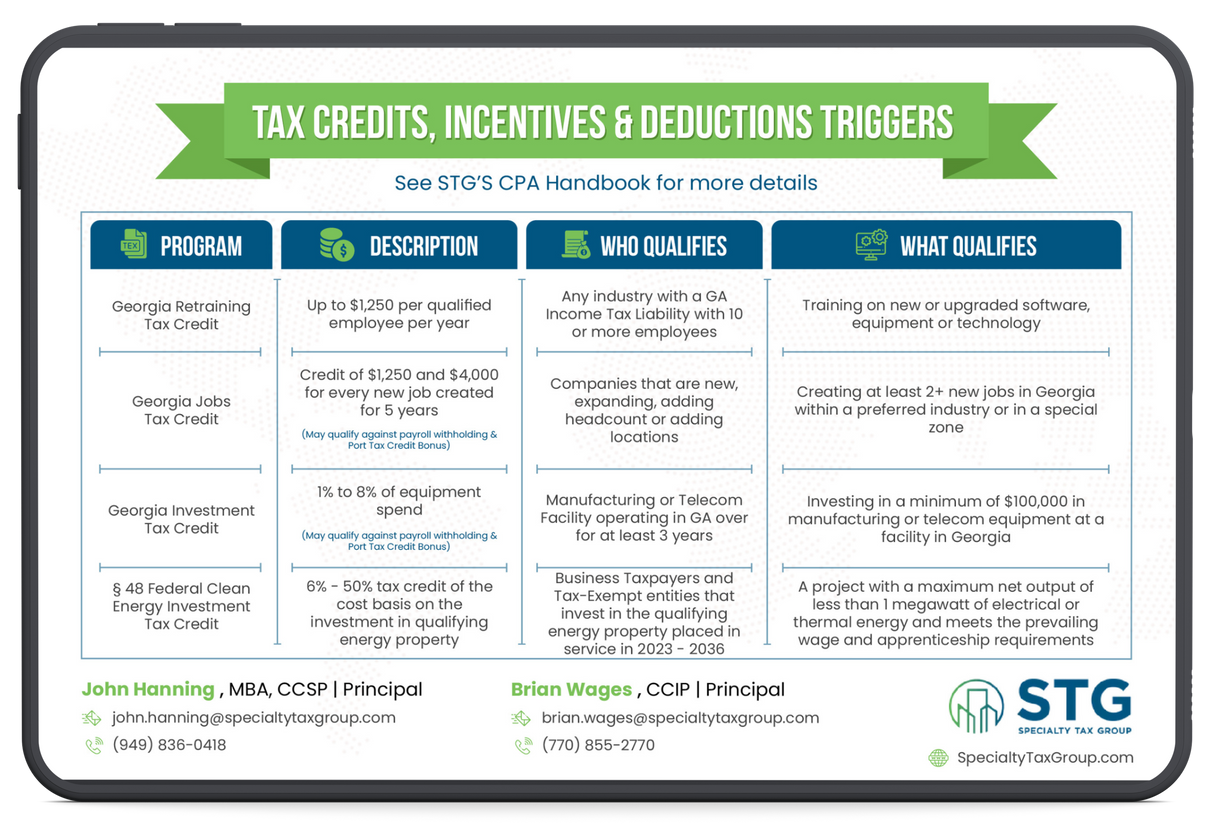

Two of the most impactful programs—the R&D Tax Credit and the Georgia Retraining Tax Credit—reward companies for the work they’re already doing: developing processes, improving equipment, testing new ideas, and training employees. These credits help manufacturers stay competitive, but most companies either under-claim them or miss them entirely.

This guide breaks everything down in clear, straightforward language so you can understand what you qualify for, how these credits work, and how to use them to keep more capital inside your business.

What Tax Incentives Are Available for Manufacturing Companies?

Manufacturing companies often qualify for more incentives than they realize. The misconception that these programs apply only to high-tech or research-focused companies stops many from even exploring their options.

The Credits Most Manufacturers Qualify For but Rarely Claim

- R&D Tax Credit: Rewards companies that solve problems, improve processes, develop or refine products, or make production more efficient.

- Georgia Retraining Tax Credit: Helps cover the cost of training employees on new equipment, technology, or updated workflows.

Both programs have industrial sectors in mind. If your business builds, refines, tests, or trains—there’s likely money on the table.

Understanding the R&D Tax Credit (Research & Development Tax Credit)

What Counts as “R&D” in a Manufacturing Environment?

In manufacturing, R&D rarely looks like a laboratory experiment. It often happens right on the production floor during day-to-day problem-solving.

Qualifying work can include:

- Improving or redesigning manufacturing processes

- Testing different materials or methods

- Building prototypes or refining tooling

- Introducing automation or robotics

- Improving software systems

- Reducing waste, defects, or cycle times

Efforts to improve performance, solve technical issues, or create a product or process improvement are great examples of what can often count.

Common Misconceptions That Prevent Manufacturers From Claiming

- “We’re not a tech company.”

Most R&D claims actually come from traditional manufacturers—not Silicon Valley startups. - “Nothing we did was groundbreaking.”

You don’t need a major invention. Incremental improvements still can qualify. - “We’ve always done this work.”

Continuous innovation is still innovation. Continuous improvement efforts can still qualify.

Actual Activities That Can Qualify (Plain-Language Checklist)

Think about whether your team has:

- Experimented with new materials

- Enhanced equipment for better performance

- Developed product improvements

- Tested new production methods

- Tried to reduce scrap or downtime

- Improved durability or quality

If so, you’re likely engaging in R&D without possibly labeling it that way.

How Much Manufacturers Can Save With the R&D Credit

Manufacturers can often see some of the biggest benefits because they employ engineers, technicians, and teams dedicated to improvement.

Typical outcomes include:

- Significant federal and state dollar-for-dollar tax credit savings on a company's tax liability

- Potential opportunities to amend prior years’ returns

Even small shops can often see meaningful savings.

The Georgia Retraining Tax Credit Explained

What the Retraining Credit Is

The Georgia Retraining Tax Credit is one of the state’s most business-friendly incentives. It reimburses companies for training employees on new equipment, software, or processes—something manufacturers do constantly.

Whenever your team needs time to learn a new system, this credit can potentially help offset those costs.

Qualifying Activities for the Georgia Retraining Credit

Training can be eligible when employees must learn something new to remain productive.

Examples include:

- Operating new machinery or technology

- Learning updated software (ERP, CAD, CAM, robotics interfaces)

- Adopting safer or more efficient workflows

- Implementing new automation tools

- Cross-training across departments

If training took time, guidance, or hands-on practice, it likely can qualify.

How Much You Can Save With Georgia’s Retraining Credit

The credit can currently cover up to 50% of eligible training expenses, such as:

- Employee wages during retraining

- Costs of instructors and teaching materials

- Reasonable travel expenses

Currently, the credit is up to $500 per full-time employee for each training program, with an annual maximum of $1,250 per employee.

Which Credit Is Right for Your Manufacturing Company?

Quick Side-by-Side Comparison

| Credit | Best For | Key Benefit |

|---|---|---|

| R&D Tax Credit | Product / manufacturing process improvements, testing, product development | Reduces federal and state tax liability through dollar-for-dollar tax credits |

| Georgia Retraining Credit | Teaching employees new skills, equipment, or software | Receive a tax credit covering 50% of eligible training costs helping reduce your Georgia income tax liability |

Most manufacturers don’t choose between the two—they use both.

How Companies Maximize Their Savings by Claiming Both

These credits often apply to different stages of the same project. For example:

- You test and refine a new production method →

R&D Credit

- You train employees to use the new equipment →

Retraining Credit

Together, they create a strong financial advantage and unlock savings across your entire operation.

How to Know if Your Manufacturing Company Qualifies

Fast Eligibility Checklist (Yes/No Questions)

You may qualify if you answer “yes” to any of the following:

- Did you upgrade or replace equipment in the past few years?

- Have you changed or improved production processes?

- Are you using new software or automation tools?

- Have you tested new materials or product variations?

- Did you reduce waste, scrap, or downtime?

- Have employees been trained on new equipment or workflows?

Most manufacturers check multiple boxes.

How to Claim These Tax Credits Without Making Costly Mistakes

The Step-by-Step Claiming Process

Here’s how the process usually works:

- Initial 30-minute feasibility call to determine eligibility and explain our process

- Client provides necessary data

- Qualitative detail call with the client regarding activities performed

- STG performs calculation and documentation

FAQ — Rising Questions Manufacturers Now Ask

Do small manufacturing companies qualify for these credits?

Yes. Even small shops qualify if they improve processes, train employees on new equipment, or troubleshoot technical challenges.

Can we still claim credits for past years?

Yes. You can generally amend returns for up to three previous tax years to capture missed credits.

What if our projects “failed”—do they still qualify?

Yes. Attempts count. The IRS allows R&D claims even when the final outcome didn’t work as expected.

Don’t Leave Tax Savings Unclaimed

Manufacturers innovate constantly—often without recognizing that the work they do every day qualifies for major tax incentives. Whether you're experimenting with new processes, upgrading equipment, or training employees, programs like the R&D Tax Credit and the Georgia Retraining Credit can deliver meaningful financial relief.

Understanding and leveraging these incentives isn’t just about reducing taxes—it's about strengthening your company’s ability to grow, invest, and stay competitive. If you're unsure where to start or want a clearer picture of your potential savings, Specialty Tax Group (STG) can evaluate your eligibility and guide you through the entire process. A 30-minute introductory call will determine eligibility and explain our process for both credits

2024 Tax Guide